- 29 Posts

- 7 Photos

- 0 Videos

- Married

- 18/08/1989

- Followed by 1 people

© 2025 Mold Manufacturer  English

English

Recent Updates

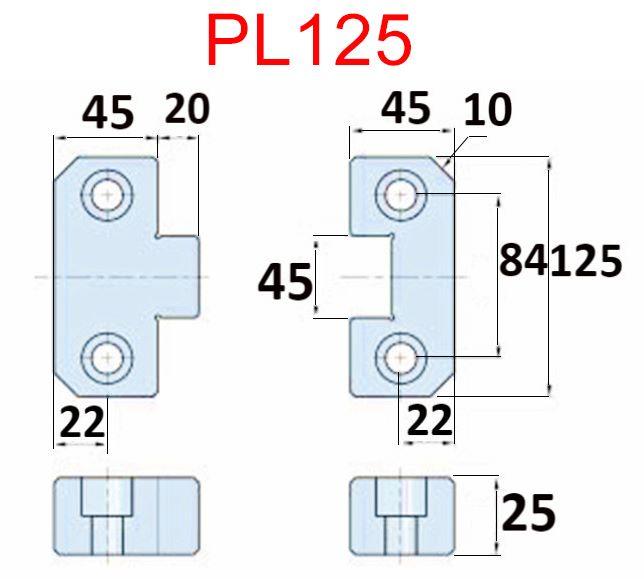

- Square Locator Block PL Mold Helper Side Lock PL125 New$13.6In stockChinaItem: PL125

Steel: Amount to YK30

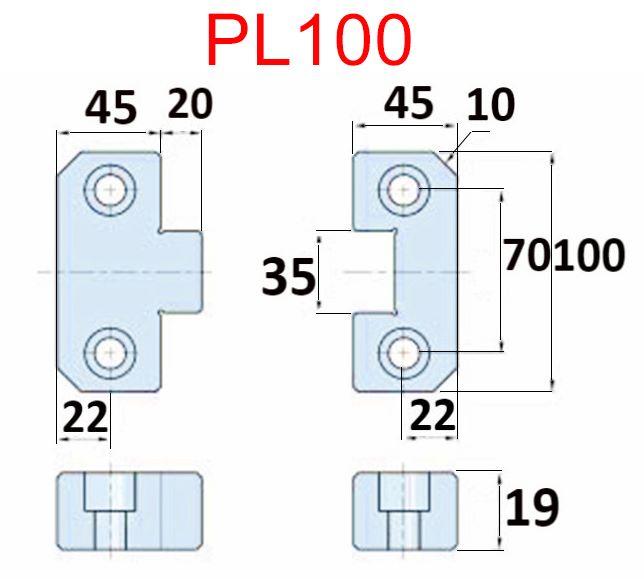

Hardness: 45-50HRCItem: PL125 Steel: Amount to YK30 Hardness: 45-50HRC0 Comments 0 SharesPlease log in to like, share and comment! - Square Locator Block PL Mold Helper Side Lock PL100 New$8.6In stockChinaItem: PL100

Steel: Amount to YK30

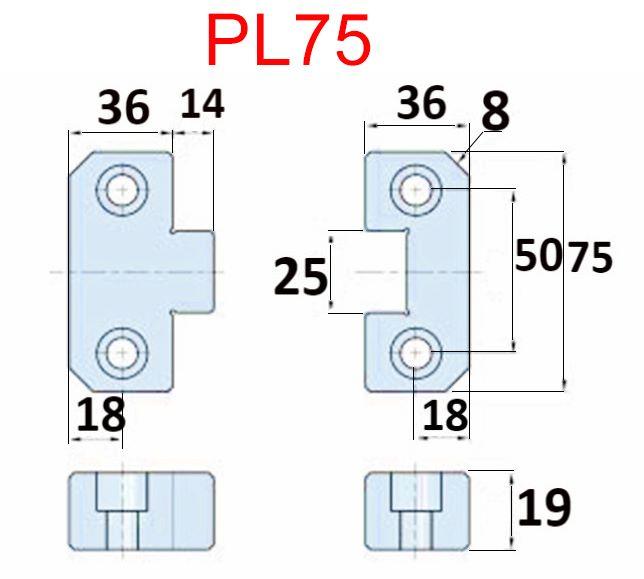

Hardness: 45-50HRCItem: PL100 Steel: Amount to YK30 Hardness: 45-50HRC0 Comments 0 Shares - Square Locator Block PL Mold Helper Side Lock PL75 New$5.8In stockChinaItem: PL75

Steel: Amount to YK30

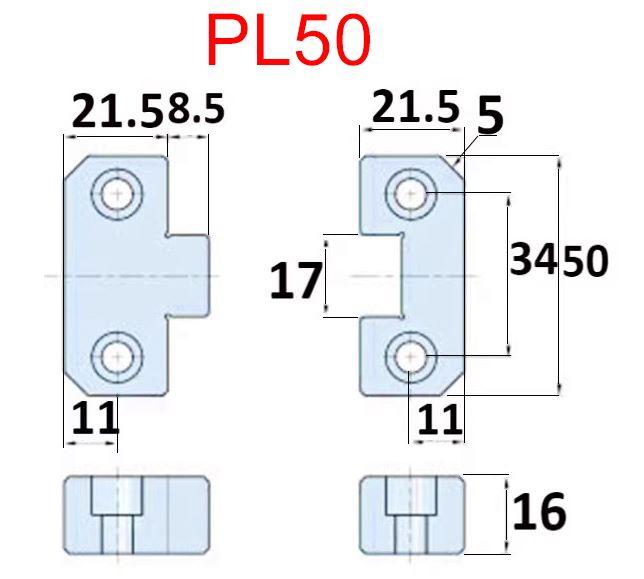

Hardness: 45-50HRCItem: PL75 Steel: Amount to YK30 Hardness: 45-50HRC0 Comments 0 Shares - Square Locator Block PL Mold Helper Side Lock PL50 New$3In stockChinaItem: PL50

Steel: Amount to YK30

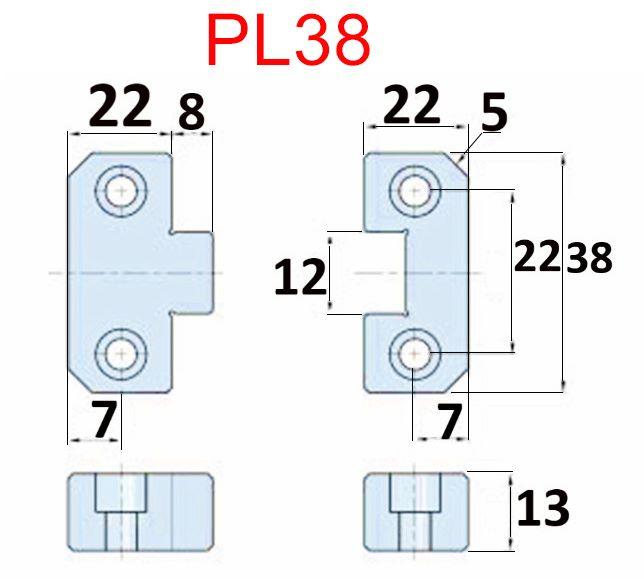

Hardness: 45-50HRCItem: PL50 Steel: Amount to YK30 Hardness: 45-50HRC0 Comments 0 Shares - Square Locator Block PL Mold Helper Side Lock PL38 New$2.9In stockChinaItem: PL38

Steel: Amount to YK30

Hardness: 45-50HRCItem: PL38 Steel: Amount to YK30 Hardness: 45-50HRC0 Comments 0 Shares - What is the polarity effect and coverage effect of electrodes?When we EDM the mold, both the positive electrode and the negative electrode will be corroded by different degrees of electrode, even if the corrosion amount of the two electrodes of the same material is different, we will find that one electrode is more corroded than the other electrode. This phenomenon is usually called the polarity effect. If the two electrode materials are different, the...0 Comments 0 Shares

- Several ways of injection mold processing driveThe drive and driving force of the injection mold processing movement (pressing force, mold clamping force, material drop weight, extrusion force, etc.) are provided by the power of the forming machine tool and equipment through the transmission mechanism. Electromechanical drive: such as punching machines, friction presses, roll forging machines, etc., are powered and rotated by electric...0 Comments 0 Shares

- Common issues on injection mold, why the part stuck on the gateThe structural form of the injection mold and the processing quality of the mold directly affect the quality and production efficiency of the plastic parts. Sometimes there might have such problems, for example, the injection molded part cannot drop off freely. The part is stuck on the gate. During the injection molding process, the gate sticks to the gate sleeve and is not easy to come out....0 Comments 0 Shares

- Common issues on injection mold, poor cooling or water leaksThe cooling effect of the mold directly affects the quality and production efficiency of the product, such as poor cooling, large shrinkage of the product, or uneven shrinkage and deformation of the warped surface. On the other hand, the whole or part of the mold is overheated, so that the mold cannot be formed normally and production is stopped. The design and processing of the cooling system...0 Comments 0 Shares

- Common issues on injection mold, moving plate bendingWhen the mold is injected, the molten plastic in the mold cavity produces a huge back pressure, generally 600 ~ 1000 kg/cm2. Mold makers sometimes do not pay attention to this problem, and often change the original design size, or replace the moving template with low-strength steel plates. In the mold with ejector ejector, due to the large span between the seats on both sides, the template...0 Comments 0 Shares

More Stories